SF6 Gas Recycling: Ensuring Environmental Sustainability and Operational Efficiency

SF6 (sulfur hexafluoride) gas is renowned for its exceptional insulating and arc-extinguishing properties, making it indispensable in high-voltage electrical equipment such as circuit breakers and switchgear. However, SF6 is also a potent greenhouse gas with a significant global warming potential. As environmental regulations tighten and the push for sustainability grows, SF6 gas recycling has become a critical process. This article delves into the significance of SF6 gas recycling the steps involved, and its benefits for both the environment and industry.

Understanding SF6 Gas

SF6 is a colorless, odorless, and inert gas that excels in insulating electrical equipment and suppressing electrical arcs. Its effectiveness in these applications has made it a popular choice in the electrical industry. Despite its advantages, SF6 has a global warming potential that is approximately 23,500 times greater than carbon dioxide (CO2). This makes managing and recycling SF6 crucial for minimizing its environmental impact.

The Importance of SF6 Gas Recycling

The recycling of SF6 gas addresses several environmental and operational concerns:

- Environmental Protection: SF6 gas, if not properly managed, can leak into the atmosphere and contribute to global warming. Recycling helps prevent these emissions by recovering and reusing the gas.

- Regulatory Compliance: Many countries and regions have strict regulations regarding SF6 emissions. Recycling SF6 helps organizations comply with these regulations and avoid potential fines.

- Resource Efficiency: Recycling SF6 reduces the need for new gas production, conserving natural resources and reducing the overall environmental footprint of SF6 use.

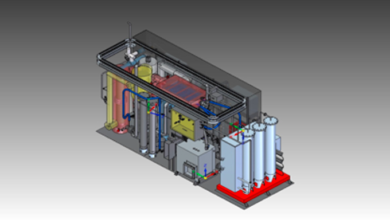

SF6 Gas Recycling Process

The recycling process involves several key stages to ensure that SF6 gas is effectively recovered, purified, and reused:

- Recovery: SF6 gas is extracted from electrical equipment using recovery systems designed to capture and contain the gas. This step is typically performed during maintenance or decommissioning of equipment.

- Purification: The recovered SF6 gas is purified to remove impurities such as moisture, air, and other contaminants. This is usually achieved through filtration and drying processes to restore the gas to its original quality.

- Storage: After purification, the SF6 gas is stored in high-pressure containers. Proper storage is crucial to prevent leaks and maintain the integrity of the gas until it is needed for reuse.

- Reuse: The purified SF6 gas is reused in new or existing electrical equipment. This reduces the need for virgin SF6 and supports sustainable practices.

- Disposal: Any SF6 gas that cannot be reused is disposed of in compliance with environmental regulations. Specialized disposal methods ensure that the gas does not contribute to atmospheric pollution.

Benefits of SF6 Gas Recycling

1. Reduces Greenhouse Gas Emissions

Recycling SF6 significantly mitigates its impact on global warming by preventing emissions. By reusing the gas, the amount of SF6 released into the atmosphere is minimized, supporting global climate goals.

2. Lowers Operational Costs

Recycling SF6 can lead to cost savings by reducing the need for purchasing new gas. The process of recovering and purifying SF6 is often more economical compared to sourcing fresh SF6, especially in large-scale applications.

3. Enhances Regulatory Compliance

Implementing SF6 recycling practices helps organizations meet regulatory requirements related to SF6 emissions. Compliance with these regulations not only avoids penalties but also demonstrates a commitment to environmental responsibility.

4. Extends Equipment Lifespan

Maintaining the quality of SF6 gas through recycling helps ensure that electrical equipment operates efficiently and has a longer service life. Clean, recycled SF6 supports the reliable performance of high-voltage systems.

5. Promotes Sustainability

Recycling SF6 aligns with broader sustainability efforts by conserving resources and reducing waste. By adopting recycling practices, organizations contribute to a more sustainable and environmentally friendly approach to managing electrical infrastructure.

Considerations for Effective SF6 Gas Recycling

1. Advanced Technology

Investing in advanced recycling technology is essential for effective SF6 gas management. Modern recovery and purification systems ensure high-quality results and efficient operation.

2. Skilled Personnel

Proper training and expertise are critical for handling and processing SF6 gas. Skilled personnel are necessary to operate recycling equipment safely and effectively.

3. Safety Protocols

Implementing robust safety protocols is crucial when dealing with SF6 gas. This includes using personal protective equipment (PPE) and following established procedures to handle the gas safely.

4. Regulatory Awareness

Staying informed about current regulations and standards related to SF6 gas is vital. Organizations must ensure that their recycling practices comply with local and international requirements.

5. Collaboration with Experts

Partnering with specialized SF6 recycling service providers can enhance the effectiveness of the recycling process. These experts offer valuable knowledge and resources to optimize SF6 management.

Conclusion

SF6 gas recycling is a vital process for managing the environmental impact of this potent greenhouse gas while supporting the efficient operation of electrical systems. By recovering, purifying, and reusing SF6 gas, organizations can reduce greenhouse gas emissions, lower operational costs, and comply with regulatory requirements. Effective SF6 gas recycling involves investing in technology, ensuring skilled personnel, adhering to safety protocols, and staying informed about regulations. Embracing SF6 gas recycling is a key step towards sustainable and responsible management of electrical infrastructure.